The Rotomolding Advantage

Rotomolding, also called Rotational Molding, or Rotocast is a thermoplastic process that produces hollow parts.

Placing resin material into the mold and then rotating that mold in a oven until the resin material melts and coats the inside of the mold.

The mold is then cooled and the part is removed from the mold. The mold can now be prepped again to be refilled with plastic resin.

Rotational Molding Advantages

Molded in Graphics

Need to add a company logo, warning sign, or instructions? With a mold in graphic: it's permanent, durable, tested UV, chemicals, weather resistant. We offer more customization to you plastic part. We work with Mold in Graphics to create exactly what you need. A molded in graphic can offer your brand recognition.

Custom Colors

Getting the correct color you want. We use high-intensity mixing equipment that ensures proper color throughout the part, regardless of the size or how complex your mold is.

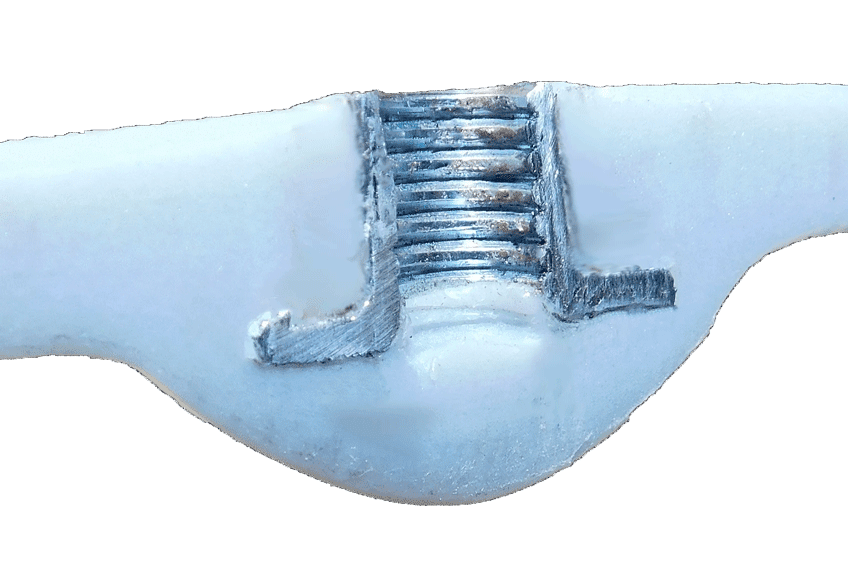

Molded Inserts

Inserts are easily molded into your plastic part. No need for additional nuts or fittings. Molded fittings allow more design and production choices for your product.

Send us a message

Contact us today and our friendly support team will reach out as soon as possible.